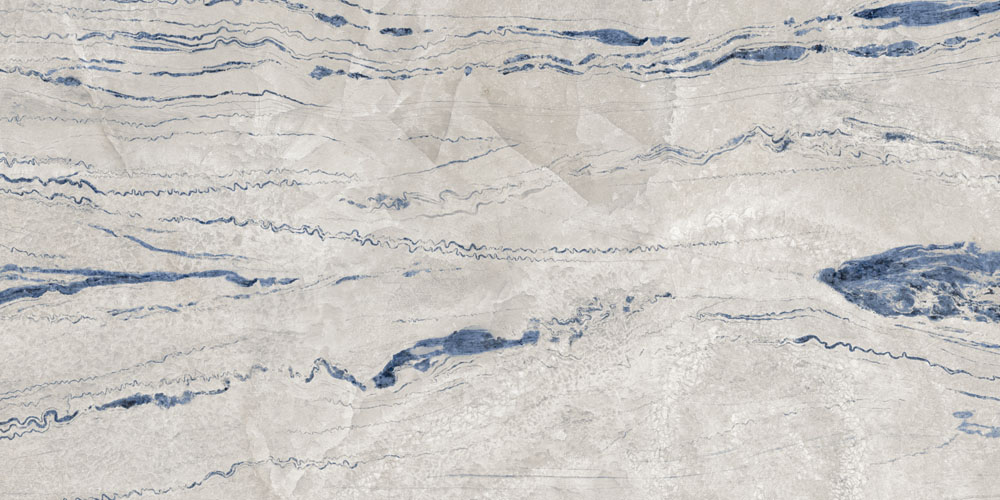

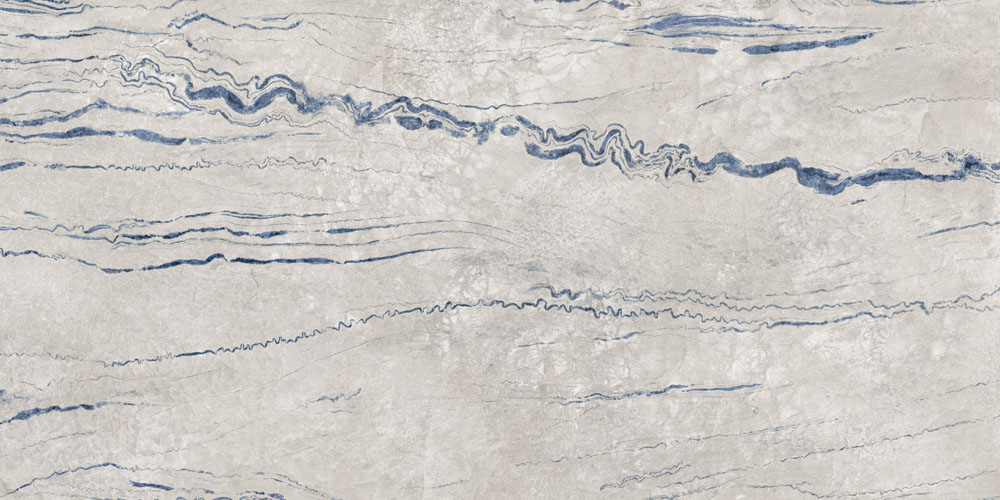

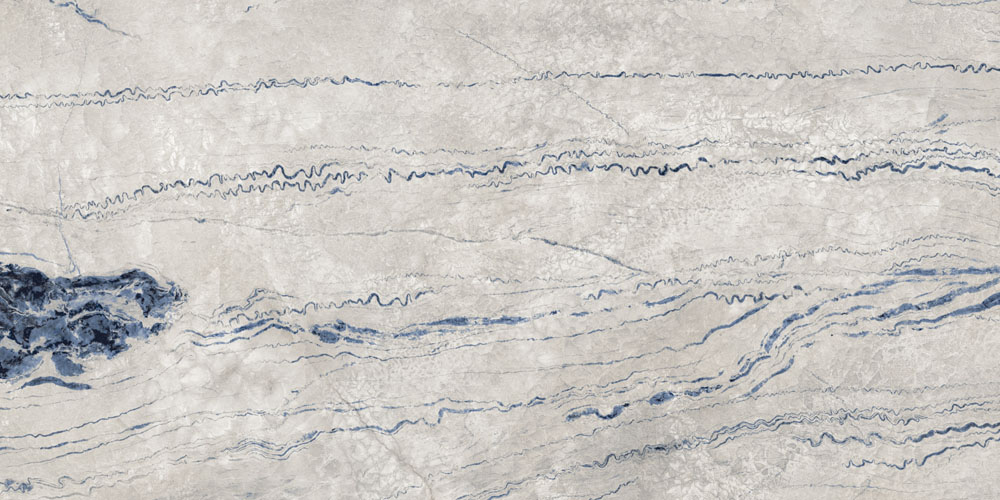

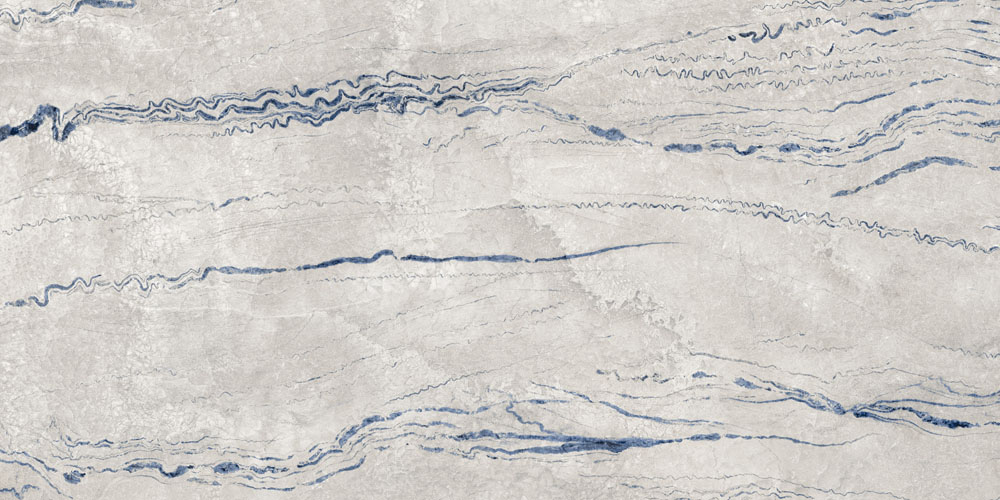

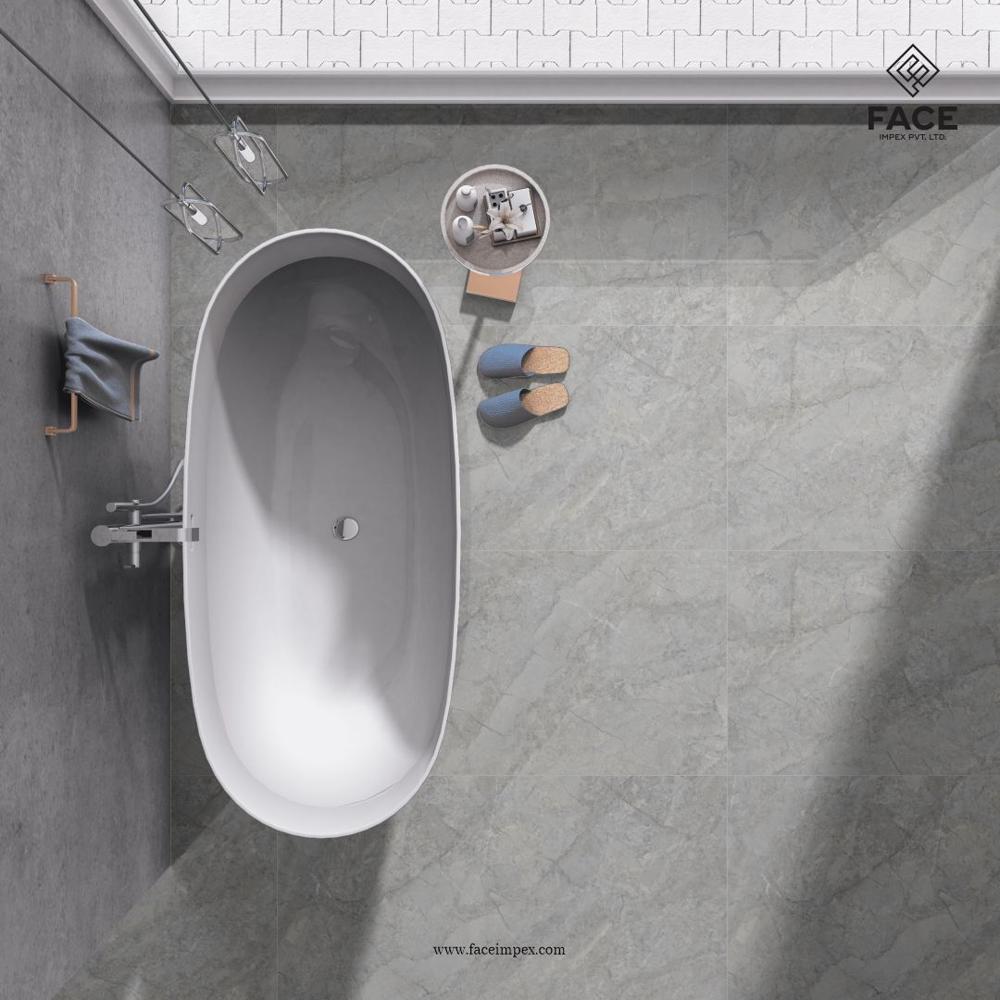

DLG - 4 Manufacturer of vitrified tiles in India offering high quality designs for global export

DLG - 4 Manufacturer of vitrified tiles in India offering high quality designs for global export Specification

- Tile Type

- Vitrified Tiles

- Tile Material

- Porcelain

- Application

- Floor Tiles

- Surface Treatment

- Glazed Tiles, Polished Tiles

- Tile Finish

- Gloss

- Tile Sort

- Plain

- Color

- Grays, Purples / Lavenders

- Size

- 60X120CM

- Thickness

- 8.5 Millimeter (mm)

- Feature

- Acid-Resistant, Antibacterial, Non-Slip, Wear-Resistant, Firebrick, Heat Insulation

- Design

- DLG - 4

About DLG - 4 Manufacturer of vitrified tiles in India offering high quality designs for global export

About Porcelain Floor Tiles DLG - 4

GLAZED POLISHED PORCELAIN FLOOR TILES

SIZE :- 600x1200mm

COVARAGE :- 1.44/sqm

THICKNESS :- 8.5mm Approx.

MOQ :- 972 sqm

FACE IMPEX PVT.LTD - INDIA

We are manufacturing and exporting of the ceramic and porcelain tiles since 2006 and we have below format available:

PORCELANTO: (VITRIFIED W.A - 0.5 %)

|600 x 600 | 600 x 1200 | 800 x 800 | 800 x 1600 | 200 x 1200 mm and Bigger Slab Tiles

CERAMICO: (CERAMIC BODY W. A 10 TO 14 % )

|300 x 600 | 300 X 450 | 250 X 400 | 250 X 375 | mm |

DIFFERENT FINISH AVAILABLE:Polished | Matt | Carving | High Gloss | Sugar |

We have with updated technology and in house R& D team and Quality control team are there! Our production capacity is 15000 sq mt per day and with +60 countries in export our product in worldwide.

CERTIFICATION:We have ISO 9001 :2015 and 14001: 2015, CE certificate

Innovative Design & Durability

DLG - 4 vitrified tiles stand out due to their elegant, contemporary design and a variety of advanced functional qualities. Manufactured using premium porcelain, these glazed and polished tiles deliver long-lasting performance and maintain their finish even under demanding conditions. The plain tile sort ensures a versatile appearance, suitable for modern residential and commercial interiors alike.

Suitable for Global Flooring Projects

Offering a 60x120 cm size with a glossy, slip-resistant surface, DLG - 4 vitrified tiles are expertly engineered for flooring applications worldwide. As an Indian manufacturer and exporter, DLG is equipped to supply large-scale orders for projects in diverse climates and settings, ensuring international standards are met for both quality and safety.

FAQs of DLG - 4 Manufacturer of vitrified tiles in India offering high quality designs for global export:

Q: How are DLG - 4 vitrified tiles manufactured to ensure quality and durability?

A: DLG - 4 vitrified tiles are crafted using premium porcelain material and advanced vitrification techniques, resulting in a dense, durable tile. The manufacturing process includes high-pressure compaction and firing at elevated temperatures, which ensures each tile is resistant to wear, moisture, and impact.Q: What are the main benefits of choosing DLG - 4 vitrified tiles for flooring projects?

A: Choosing DLG - 4 vitrified tiles offers benefits such as acid resistance, antibacterial protection, non-slip surface, wear resistance, as well as firebrick and heat insulation capabilities. This makes the tiles excellent for long-term use in residential, commercial, and high-traffic environments.Q: Where can DLG - 4 vitrified tiles be installed for best results?

A: DLG - 4 vitrified tiles are optimized for floor applications in spaces like living rooms, offices, hotel lobbies, and shopping centers. Their non-slip, wear-resistant properties and elegant appearance make them ideal for both private and public interiors where safety and style are priorities.Q: What is the recommended process for installing DLG - 4 vitrified floor tiles?

A: For best performance, use a level substrate and high-quality adhesive suitable for vitrified tiles. Apply the grout carefully, ensuring even spacing and a secure fit. The glazed surface makes post-installation cleaning straightforward, ensuring the tiles look pristine after installation.Q: When should I opt for DLG - 4 tiles with glazed and polished finishes?

A: Opt for the glazed and polished finish when you desire a glossy, sleek look with heightened stain resistance and ease of cleaning. These finishes enhance indoor floor aesthetics and are particularly beneficial in spaces demanding a contemporary, high-end vibe.Q: How do the antibacterial and non-slip features enhance the usage of DLG - 4 tiles?

A: The antibacterial treatment helps inhibit the growth of microbes, promoting a hygienic environment, while the non-slip surface significantly reduces the risk of slips and falls, making these tiles suitable for homes, workplaces, and commercial settings.

Price 3.35 USD ($)/ Square Meter

- Minimum Order Quantity

- 972 Square Meters

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 600 X 1200 Polished Tiles Category

DLG - 131 60X120CM PORCELAIN TILES

Price 473.0 INR / Box

Minimum Order Quantity : 1000 Boxes

Tile Material : Porcelain

Color : Whites

Usage : Interior Tiles

Tile Sort : Plain

DLG - 69 60X120CM PORCELAIN TILES

Price 475.0 INR / Box

Minimum Order Quantity : 1000 Boxes

Tile Material : Porcelain

Color : Grays

Usage : Interior Tiles

Tile Sort : Plain

DLG - 186 60X120CM PORCELAIN TILES

Price 475.0 INR / Box

Minimum Order Quantity : 1000 Boxes

Tile Material : Porcelain

Color : Whites

Usage : Interior Tiles

Tile Sort : Plain

DLG - 162 60X120CM PORCELAIN TILES

Price 475.0 INR / Box

Minimum Order Quantity : 1000 Boxes

Tile Material : Porcelain

Color : Grays

Usage : Interior Tiles

Tile Sort : Plain

Send Inquiry

Send Inquiry Send SMS

Send SMS